A scale of hardness makes hardness of materials measurable, and especially in the field of geology, allows one to test, verify and ultimately help identify a mineral.

In this sense, the Mohs Scale of Hardness becomes an indispensable system for mineral identification out in the field.

A Brief History on Hardness

1773 – 1839

Scratching one mineral with another to determine the softer or harder of the two has its roots way back in c.300 BC where it was mentioned in Theophrastus in his treatise On Stones, and again in Pliny the Elder’s work Naturalis Historia in c.77 AD.

However, the scale of hardness we’re more familiar with and in use today is known as the Mohs Scale of Hardness. This was established by the German mineralogist Friedrich Mohs in 1812.

While minerals today are classified by their chemical composition based on the Strunz or Dana system, their physical attributes such as colour, streak, cleavage, fracture, refractive index, specific gravity, and hardness help in the identification of minerals.

Measurable Hardness

Hardness should not be confused with toughness, strength or tenacity, as these are different properties of a mineral altogether. As an example, diamond may be one of the hardest substance known to man (harder still are hyperdiamond and ultrahard fullerite), but diamond can be brittle as well, and hence hardness may not necessarily equate to tough.

The Mohs Scale of Hardness lists ten common minerals on a scale of 1 to 10 from softest to hardest.

It is with great pleasure that I tabulate this below with mineral specimens from the Devon Buy Collection of Fine Minerals and Crystals. I will also put alongside minerals of intermediate hardness from my collection which fall within decimal places relative to the scale.

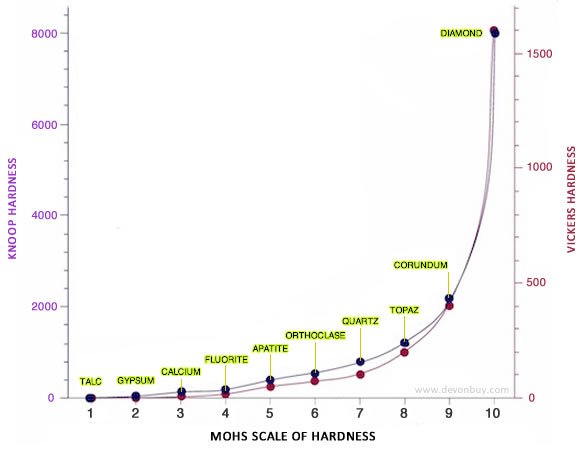

Note that the Mohs Scale does not follow a linear scale, as given by the absolute hardness in brackets below each Mohs number. This is further elaborated in the next section after the table below.

| Mohs Hardness (absolute hardness) |

Intermediate Hardness | Mineral and Formula | Specimen from Collection | Notes and Remarks |

|---|---|---|---|---|

1

(1) |

TALC Mg3Si4O10(OH)2 |

|

Very easily scratched with fingernail | |

| 1 – 2 | GRAPHITE C |

|

Think of the softness of graphite in your everyday pencil | |

| 1½ – 2 | REALGAR AsS |

|

||

2

(3) |

GYPSUM CaSO4·2H2O |

|

Can be scratched with fingernail | |

| 2½ – 3 | GOLD Au |

|

Malleable, and slightly harder than fingernail | |

3

(9) |

CALCITE CaCO3 |

|

Can be scratched with a copper coin | |

| 3 – 3½ | CERUSSITE PbCO3 |

|

||

| 3½ – 4 | MALACHITE Cu2(CO3)(OH)2 |

|

||

4

(21) |

FLUORITE CaF2 |

|

Very easily scratched with a knife | |

| 4½ – 5 | HEMIMORPHITE Zn4Si2O7(OH)2·H2O |

|

||

5

(48) |

APATITE Ca5(PO4)3(F,Cl,OH) |

|

Scratched with knife with difficulty | |

| 5½ – 6 | ARSENOPYRITE FeAsS |

|

About the hardness of ordinary glass at 5.5 | |

6

(72) |

ORTHOCLASE KAlSi3O8 |

|

Scratches glass with some difficulty | |

| 6 – 6½ | PYRITE FeS2 |

|

Almost similar in hardness to metal file tool made of steel | |

7

(100) |

QUARTZ SiO2 |

|

Scratches glass easily | |

| 7 – 7½ | STAUROLITE Fe2Al9Si4O22(OH)2 |

|

||

| 7½ – 8 | EMERALD Be3Al2Si6O18 |

|

||

8

(200) |

TOPAZ Al2SiO4(F,OH)2 |

|

Scratches glass very easily | |

9

(400) |

CORUNDUM Al2O3 |

|

Cuts glass | |

10

(1600) |

DIAMOND C |

|

Cuts glass and almost everything else |

Absolute Hardness and a non-Linear Scale

Notice that in the table above, the absolute hardness is given for each number on the Mohs Scale of Hardness. This is because, while the numbers on the Mohs Scale moves up from 1 to 10 like a linear scale, it is in fact not a linear one. Meaning, Diamond at 10 is NOT twice as hard as Apatite at 5. Looking at the absolute hardness of these two minerals, Diamond is over 30 times harder than Apatite. If the figures of absolute hardness were plotted on a chart, the actual hardness would show that the Mohs Scale follows a logarithmic chart as given below.

Specialist Tools to Test for Hardness

The hardness of a mineral can be tested by using specialist tools such as a hardness pick set, such as the one shown at right. The set usually includes 4 picks with points on both ends, incremental in hardness from 2 to 9.

A scratch test is done by applying pressure on the mineral with a chosen point of hardness index, and depending on the hardness of the mineral, the point will either leave a scratch on a softer mineral, slide without any scratches on a mineral of equal hardness as the point itself, or leave a trail of metal shavings from the point if applied on a harder mineral (point of Mohs index 2 is usually made of plastic, and hence will not show any metal wear on the mineral). A sharpening stone is sometimes included for maintenance of the set.

To purchase a hardness pick set, please see the links below.

RELATED: See the Devon Buy Collection of Fine Minerals and Crystals